Na Andy mai ka hale hana Baiyear

Hoʻopuka ʻia ma Nowemapa 1, 2022

ʻAʻole i loaʻa ka wehewehe piha ʻana o ka lau metala.Wahi a ka wehewehe ʻana i loko o kahi puke pai ʻoihana haole, hiki ke wehewehe ʻia: ʻO ka metala he kaʻina hana anuanu no nā papa metala lahilahi (maʻamau ma lalo o 6mm), me ka ʻohi, kuʻi / ʻoki / hui ʻana, pelu ʻana, wili, riveting, splicing. , hana (e like me ke kino kaʻa), etc. ʻO kāna hiʻohiʻona kupaianaha ʻo ia ka mānoanoa o ka ʻāpana like.

He hana koʻikoʻi ka ʻoki ʻana i ka metala no ka hana ʻana i nā huahana metala.Hoʻopili ia i ka ʻoki kuʻuna, ka blanking, ka bending forming a me nā ʻano hana ʻē aʻe a me nā ʻāpana kaʻina hana, a me nā ʻano hana make stamping ʻokoʻa a me nā ʻāpana kaʻina hana, nā ʻano hana hana a me nā ʻano hana, a me nā ʻenehana stamping hou a me nā ʻenehana hou.

No kēlā me kēia ʻāpana metala, loaʻa iā ia kahi kaʻina hana, ʻo ia ke kaʻina hana ʻenehana.Me ka ʻokoʻa o ke ʻano o nā ʻāpana metala, ʻokoʻa paha ke kaʻina hana ʻenehana, akā ʻaʻole i ʻoi aku ka nui o nā helu aʻe.

1. E hoʻolālā a kaha kiʻi i ke kaha kiʻi ʻāpana o kona mau ʻāpana metala, ʻike ʻia hoʻi he ʻekolu manaʻo.ʻO kāna hana ka hōʻike ʻana i ke ʻano o kāna mau ʻāpana metala ma o nā kaha kiʻi.

2. E kaha kiʻi i wehe ʻia.ʻO ia hoʻi, wehe i kahi ʻāpana me kahi ʻano paʻakikī i kahi ʻāpana palahalaha.

3. Paha.Nui nā ʻano o ka hoʻopaʻa ʻana, ʻo ka mea nui ma kēia mau ʻano:

a.ʻOki mīkini ʻoki.ʻO ia ka hoʻohana ʻana i ka mīkini ʻako e ʻoki i ke ʻano, ka lōʻihi a me ka laula o ke kaha kiʻi i hoʻonui ʻia.Inā loaʻa ke kuʻi a me ke ʻoki kihi, a laila e hoʻohuli i ka mīkini kuʻi e hoʻohui i ke kuʻi make a me ke ʻoki kihi e hana.

b.Punch blanking.ʻO ia ka hoʻohana ʻana i ke kuʻi e kuʻi i ka ʻāpana palahalaha ma hope o ka wehe ʻia ʻana o nā ʻāpana ma ka pā i hoʻokahi a ʻoi aku paha nā ʻanuʻu.Loaʻa iā ia nā pōmaikaʻi o nā hola kanaka pōkole, kiʻekiʻe kiʻekiʻe, a hiki ke hōʻemi i nā kumukūʻai hana.

c.NC CNC blanking.I ka NC blanking, ʻo ka hana mua ke kākau i ka papahana machining CNC.ʻO ia ka hoʻohana ʻana i ka polokalamu polokalamu e kākau i ke kiʻi hoʻonui i huki ʻia i kahi papahana hiki ke ʻike ʻia e ka mīkini mīkini NC CNC.E hahai i kēia mau papahana i kēlā me kēia ʻanuʻu ma luna o ka pā hao.

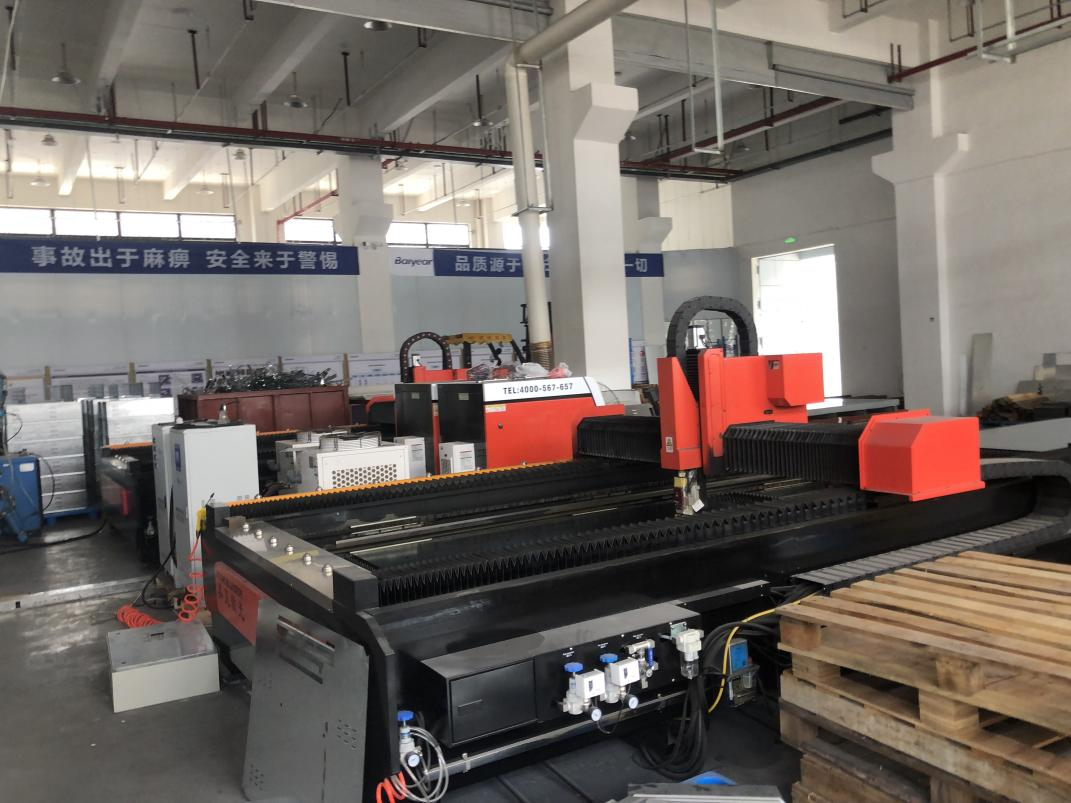

d.ʻOki laser.Hoʻohana ʻo ia i ke ʻano ʻoki laser e ʻoki i ke ʻano o kona mau ʻāpana palahalaha ma luna o kahi pā hao.

4. ʻO ke kī ʻana a me ka paʻi ʻana.Kapa ʻia ʻo Flanging ʻo ka wili lua, ʻo ia ka huki ʻana i kahi puka nui iki ma luna o kahi lua kumu liʻiliʻi, a laila kaomi i ka puka.Hiki i kēia ke hoʻonui i kona ikaika a pale i ka paheʻe.Hoʻohana maʻamau no ka hana ʻana i ka pepa metala me ka mānoanoa pāʻani lahilahi.Ke nui ka mānoanoa o ka pā, e like me ka mānoanoa pā ma luna o 2.0, 2.5, a me nā mea ʻē aʻe, hiki iā mākou ke paʻi pololei me ka ʻole o ka flanging.

5. ʻO ka hana kuʻi.ʻO ka maʻamau, hoʻohana ʻia ke kuʻi ʻana a me ka ʻoki kihi, ke kī ʻana i ka blanking, ke kuʻi ʻana i ka hull convex, ke kuʻi ʻana a me ka haehae ʻana, ke kuʻi a me nā ʻano hana ʻē aʻe e hoʻohana ʻia e hoʻokō ai i ke kumu hana.Pono ka hana ʻana i nā mold e hoʻopau i ka hana.Loaʻa nā poʻo hull convex no ke kuʻi ʻana i nā hull convex, a me nā poʻo waimaka no ke kuʻi a me ka haehae.

6. Paʻi riveting.E like me kā mākou hale hana, hoʻohana pinepine ʻia nā studs riveting pressure, pressure riveting nuts, pressure riveting screws, etc.Hoʻopili ʻia i nā ʻāpana metala.

7. Kulou ana.ʻO ka piko ʻana, ʻo ia ka pelu ʻana i nā ʻāpana palahalaha 2D i ʻāpana 3D.Pono kāna hana ʻana i kahi mīkini kuʻi a me kahi make kuʻi pili e hoʻopau i ka hana.Loaʻa iā ia kekahi kaʻina piko.ʻO ka paʻi mua ʻaʻole e hoʻopilikia e hoʻopuka i ka paʻi hope e hoʻopilikia.

8. wiliwili.ʻO ka welding ka hoʻopaʻa ʻana i nā ʻāpana he nui i mea e hoʻokō ai i ke kumu o ka hana ʻana a i ʻole e weld i ka ʻaoʻao ʻaoʻao o kahi ʻāpana e hoʻonui ai i kona ikaika.ʻO nā ʻano hana maʻamau e pili ana i kēia mau mea: CO2 gas shielded welding, argon arc welding, Spot welding, robot welding, etc. ʻO ke koho ʻana o kēia mau hana welding e pili ana i nā koi maoli a me nā mea.ʻO ka ʻōlelo maʻamau, hoʻohana ʻia ka hoʻoheheʻe ʻana i ke kinoea CO2 no ka wili hao;hoʻohana ʻia ka welding argon arc no ka wiliwili pā alumini;Hoʻohana nui ʻia ka welding robot i nā mea hoʻohana ʻia i ka wā nui nā ʻāpana a lōʻihi ka wili wili.E like me ka hoʻopaʻa ʻana i ka cabinet, hiki ke hoʻohana ʻia ka welding robot, hiki ke mālama i nā hana he nui a hoʻomaikaʻi i ka hana hana a me ka maikaʻi o ka welding.

9. Lapaʻau ʻili.Hoʻohana maʻamau ka mālama ʻana i ka phosphating film, electroplating multicolored zinc, chromate, baking paint, oxidation, etc.Hoʻohana ʻia kahi kiʻiʻoniʻoni pale e pale i ka oxidation;ʻo ka lua, ʻo ia ka hoʻonui ʻana i ka pili ʻana o kāna pena bakena.Hoʻohana mau ʻia ka zinc color electroplating no ka hoʻomaʻamaʻa ʻana i ka ʻili o nā papa i ʻōwili ʻia;Hoʻohana pinepine ʻia ka chromate a me ka oxidation no ka mālama ʻana i nā papa alumini a me nā profile alumini;kona ili kiko'ī Hoʻoholoʻia ke koho o keʻano hana e like me nā koi o ka mea kūʻai.

10. Ahaolelo.ʻO ka mea i kapa ʻia ʻo ka hui ʻana, ʻo ia ka hoʻohui ʻana i nā ʻāpana he nui a i ʻole nā ʻāpana i kekahi ʻano e hana ai i mea piha.ʻO kekahi o nā mea e hoʻolohe ai, ʻo ia ka pale ʻana i ka mea, ʻaʻole i nā ʻōpala a me nā puʻupuʻu.ʻO ka hui ka hana hope loa i ka hoʻopau ʻana i kahi mea.Ināʻaʻole hiki ke hoʻohanaʻia ka mea ma muli o nā'ōpala a me nā puʻupuʻu, pono e hana hou a hana houʻia, kahi e hoʻopau ai i ka manawa hana nui a hoʻonui i ke kumukūʻai o ka mea.No laila, pono e uku nuiʻia i ka pale o ka mea.

Ka manawa hoʻouna: Nov-29-2022